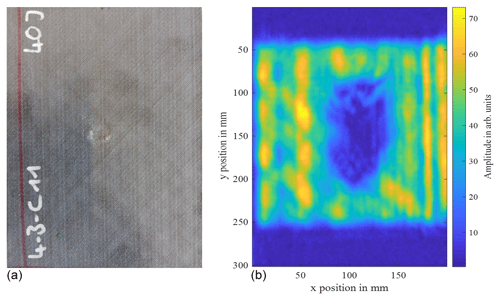

Integrated defect sensor for the inspection of fiber-reinforced plastics using air-coupled ultrasound

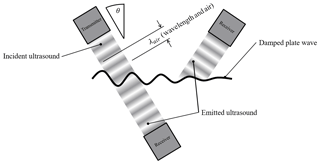

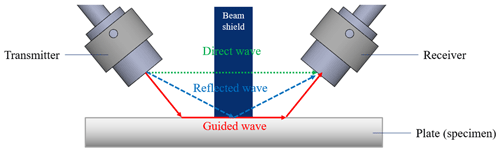

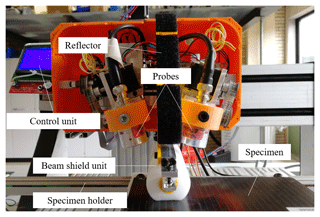

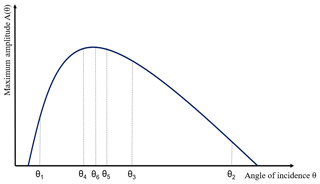

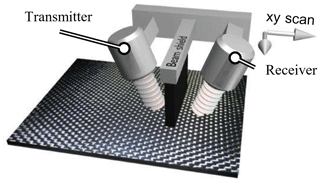

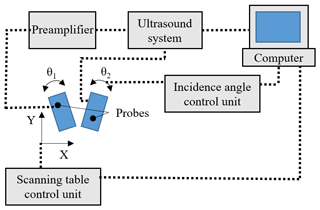

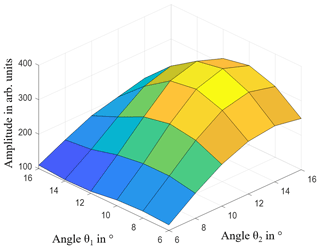

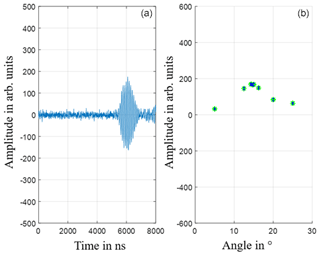

Air-coupled ultrasound (ACU) is a non-destructive testing (NDT) method with a rising significance in industrial use. Common cases where ACU is used are the testing of fiber-reinforced plastic or testing of weld joints between metal sheets. The advantage compared to contact ultrasound is the absence of a liquid, solid or gel-like couplant. The usage of a couplant is an obstacle for developers of automatic scanning systems for ultrasonic testing because it takes a huge effort to integrate a system that delivers a continuous flow of the couplant. In addition a further step of cleaning is often necessary. ACU needs specially adapted probes to compensate for the tremendous impedance difference between a solid and air. A standard method uses two ACU probes in a normal transmission mode. With slanted probes, it is possible to generate Lamb waves in plate-like materials. Because of the contact to the surrounding air, Lamb waves transmit ultrasound to the air on both sides of the plate continually. These so-called leaky Lamb waves can be used with only one accessible side, and by using a specific resonance angle, a higher signal-to-noise ratio (SNR) is achievable. In the past, the correct angle was determined using an iterative method, where the angle of incidence was changed manually while observing the amplitude level. With the stepper-motor-driven angle scanning system, introduced here, the determination of the resonance angle is possible automatically. The system allows changes of the incidence angle during the ultrasound scan too. This makes it possible to adapt the system to wall thickness changes and changes of the radii of the parts contour.