the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

The optimal distribution of axial strain amplitude in a piezoelectric vibrating energy harvester

Eliya Salman

David Rosenstock

This study considers the optimal distribution of strain amplitude in a piezoelectric vibrating energy harvester (PVEH) that maximizes the harvested energy. In many previous studies, it was tacitly assumed that a uniform distribution of axial strain in the piezoelectric layer ensures that the harvested energy is maximal. Though this assumption is intuitive, it was not supported by analysis. In this work, we derive and present a formal analytic proof confirming that, for a given amount of energy in the vibrating structure, a uniform distribution of strain in the piezoelectric layer ensures that the harvested energy is maximal.

- Article

(694 KB) - Full-text XML

- Companion paper

- BibTeX

- EndNote

Piezoelectric vibrating energy harvester (PVEH) devices have been studied for over 2 decades (Erturk and Inman, 2008, 2009, 2011). These devices are becoming increasingly relevant as potential power sources for autonomous sensors and internet of things (IoT) applications. The most prevalent PVEHs are constructed from a piezoelectric unimorph, in which an elastic cantilever is coated with a thin layer of piezoelectric material. This piezoelectric layer is sandwiched between a top electrode and a bottom electrode. When the piezoelectric unimorph is subjected to base excitations at its natural frequency, the amplitude of vibrations increases. The periodic modulation of curvature in the cantilever results in periodic modulation of axial strain in the piezoelectric layer, which can be used to harvest electric energy. The amount of energy per vibration cycle that can be harvested depends on the electric load between the electrodes (e.g., resistor for direct heating and diode bridge for charging a battery) and the frequency of vibrations (Erturk and Inman, 2008, 2009, 2011; Karami et al., 2011).

For example, if the electrodes are disconnected (or connected by an infinite resistance), no charge will be transferred between the electrodes, and a maximal potential difference will develop between them. In this case, obviously, no power will be harvested. If, in contrast, the electrodes are shorted (i.e., connected by a resistor of zero resistance), a maximal amount of charge will be transferred between the electrodes, but there will be no voltage difference between them. Clearly, in this case as well, no power will be harvested.

The maximal amount of energy that can be harvested is proportional to the charge accumulated when the electrodes are shorted and the maximal voltage induced when the electrodes are disconnected (Du et al., 2017; Lustig and Elata, 2020). In general, assuming the structure vibrates at its fundamental mode, the accumulated charge is maximal when the structure is completely covered by the piezoelectric layer and electrodes. However, for disconnected electrodes, a partial coverage of the piezoelectric layer and electrode may be necessary to achieve the maximal voltage. In many PVEH devices, the amplitude of curvature in the structure is not uniform. In cantilever structures the maximal curvature occurs in vicinity of the clamped edge. Accordingly, an electrode that covers that region of the cantilever ensures that voltage is maximal. Extending the electrode towards the free edge of the cantilever will result in a reduction in voltage amplitude. It follows that there is an optimal coverage of electrodes that maximizes the harvested energy (e.g., Du et al., 2017).

In previous studies, it was identified that an optimal planform of the unimorph cantilever may result in a uniform amplitude of axial strain in the piezoelectric layer. In this case, the voltage difference between disconnected electrodes is independent of the electrode coverage, and it follows that a full coverage of electrode maximizes the harvested energy. This has been demonstrated in PVEH devices which include a dominant edge block. Some investigations used simulations to conclude that in this case, a trapezoidal planform of the PVEH is optimal, while others used experiments to demonstrate the same conclusion (Baker et al., 2005; Benasciutti et al., 2010; Chen et al., 2009; Dietl and Garcia, 2010; Gallina and Benasciutti, 2013; Jia and Seshia, 2016; Lee et al., 2009; Miller et al., 2011). In a recent publication, we presented a new model which confirms why a trapezoidal planform is optimal and which could be used for design. For a given edge block and excitation frequency, the model explicitly provides the geometry of the PVEH with no need for simulations (Salman et al., 2024a).

In the case of PVEH unimorphs that do not include a dominant edge block, a trapezoidal planform is not optimal. For this case, it has been shown that a tapered planform defined by Bessel functions ensures that the axial strain in the PVEH is uniform (Salman et al., 2024c, 2025).

In all the abovementioned investigations, it was tacitly assumed that ensuring a uniform distribution of strain amplitude in the piezoelectric layer ensures that the harvested energy is maximized. This seems to be intuitively sensible, but it appears that no formal proof of this has ever been provided.

The aim of the present study is to provide a formal proof and show that for a given amount of vibration energy in a PVEH, a uniform distribution of axial strain amplitude ensures that the harvested energy is maximal.

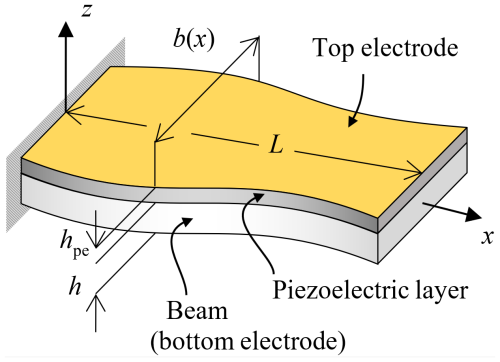

Figure 1 presents a schematic illustration of a piezoelectric cantilever unimorph that is constructed from an elastic substrate of thickness h coated with a thin piezoelectric layer of thickness hpe (hpe ≪ h). The beam length is L, and the width b(x) may be non-uniform. The elastic substrate serves as a bottom electrode for the piezoelectric layer, and a thin electrode covers the entire top surface of the piezoelectric layer. In this study, we consider a piezoelectric material of the 4 mm point group (e.g., aluminium nitride, AlN, and tetragonal lead zirconite titanate, PZT) (Ikeda, 1996; Uchino, 1997), with the poling pointing in the z direction. When the unimorph is subjected to base excitation, it can be used as a PVEH device.

Figure 1Schematic description of a PVEH unimorph cantilever. The unimorph is constructed from an elastic beam of length L, thickness h and non-uniform width b(x). The beam is coated with a thin piezoelectric layer of thickness hpe that is covered by the top electrode.

This study only considers synchronous vibrations, in which the deflection (i.e., motion in the z axis) can be described as the product of a spatial mode w(x) (where w(x) is a monotonically increasing function of x) and a single harmonic function of time sin(ωt). It is tacitly assumed that the deflection mode is a cylindrical bending such that at any cross section x, the deflection w(x) is uniform (i.e., not a function of y or z).

The aim of this study is to determine the optimal distribution of strain amplitude that maximizes the energy harvested by this device. To this end, the electric energy UE that may be harvested in one-half of a motion cycle is proportional to the product of the charge amplitude QShort that is transferred between the electrodes, if they are shorted (i.e., connected), and the amplitude of voltage difference VOpen between the electrodes, if they are open (i.e., disconnected), the following applies (Du et al., 2017; Lustig and Elata, 2020):

In Voigt notation (Ikeda, 1996; Meitzler et al., 1988), the constitutive equations of the material are given by

Here Ti is the component of stress, Si is the component of strain, is the component of the stiffness matrix (stiffness at constant electric field), Ek is the component of the electric field, Dk is the component of the electric displacement, eki is the component of the piezoelectric coefficient matrix and εkl is the component of the permittivity matrix under constant strain (the indices i and j take the values of 1 through 6, and the indices k and l take the values of 1 through 3).

In the piezoelectric layer, the poling points in the z direction such that material directions 1, 2 and 3 are parallel to the spatial axes x, y and z, respectively. According to the Euler–Bernoulli beam theory and considering that the piezoelectric layer is thin, we may deduce that within the piezoelectric layer several terms vanish. Specifically, within this layer, the shear strains and stresses are zero (i.e., 0 and 0), and the transverse stress T3 is zero because the top surface of the unimorph is stress-free. Furthermore, due to geometrical considerations, the components of the electric field and electric displacement (i.e., flux) along the x and y axes vanish (i.e., 0 and 0). Finally, for cylindrical bending, we may assume that S2= 0, and that S1 is not a function of y. Because the piezoelectric layer is thin, we may also consider S1 within the piezoelectric layer to be independent of z (this is known as the small-piezoelectricity assumption; Krommer, 2001; Tiersten, 1969) so that overall S1(x) is uniform in each cross section, though it may vary along the beam.

With these conditions, Eqs. (2) and (3) reduce to the following two coupled equations:

Here the unknowns are S1, S3, E3 and D3. The axial strain S1 is directly related to the deflection curvature, and its distribution is determined by the distributions of inertia and of bending rigidity along the beam. In this investigation, we do not wish to deduce the explicit functional form of S1 from the dynamics of the problem. Rather, we wish to find the optimal distribution of S1 for energy harvesting. Later, if it is of any interest, we may attempt to design a cantilever with specific distributions of inertia and of bending rigidity such that in periodic vibrations at some frequency ω, the distribution of the axial strain S1 will be equal to the optimal value we derived (e.g., Salman et al., 2024a). So, practically, we need to solve the two equations, Eqs. (4) and (5), for the three variables S3, E3 and D3. However, as we show next, the electrostatic boundary conditions help by imposing constrains on the values of either E3 or D3, thus leaving only two unknowns to be solved by the two equations, Eqs. (4) and (5).

2.1 Shorted electrodes

When the electrodes are shorted, the electrostatic field in the z axis vanishes. Substituting E3= 0 into Eq. (4) yields the relation between S1 and S3 for shorted electrodes:

Substituting this into Eq. (5) yields

The total charge QShort accumulated on the top electrode is given by

2.2 Open electrodes

From Eq. (4), it follows that

Substituting this into Eq. (5) yields

The total charge QOpen accumulated on the top electrode is given by

However, when the electrodes are disconnected (i.e., open), charge cannot migrate from one electrode to the other, and therefore QOpen must be identically zero. Consequently, by setting QOpen= 0, it follows from Eq. (11) that

Since the electrostatic potential over each of the electrodes is uniform, it follows that E3(x) is also uniform. Multiplying Eq. (4) by b(x) and integrating along the cantilever yields

Substituting Eq. (12) into Eq. (13) yields

It follows that the voltage VOpen is given by

In the previous section, we derived expressions for the voltage generated for open electrodes VOpen and the charge transferred for shorted electrodes QShort.

Substituting these expressions from Eqs. (8) and (15) into Eq. (1) yields

where α is a scalar that depends on material parameters and the thickness of the piezoelectric layer:

The mechanical elastic energy stored in the beam due to bending is given by

Here κ(x) is the bending curvature along the beam, EY is the Young modulus and is the second moment of the cross section at location x.

The axial strain S1(x) in the piezoelectric layer, at a given cross section x, is given by

Extracting κ(x) from Eq. (19) and substituting it into Eq. (18) yields

where .

Now, we wish to find the axial strain distribution function S1(x), which will maximize the electrostatic energy UE for an arbitrary distribution of width b(x). This can be written in the following variational notation:

where J is a functional of the argument S1(x). However, we aim to find the maximal electrostatic energy for all possible distributions of S1(x), which are associated with the same specific mechanical elastic energy .

This can be done by considering a constrained Lagrangian with a Lagrange multiplier λ:

which yields

Substituting Eqs. (16) and (20) into Eq. (23) yields

Applying the first variation for the functional Jλ (Eq. 24) with respect to S1(x) and λ yields

Our goal is to identify the function form of S1(x) at which the electrostatic energy reaches its maximum. Therefore, according to Eq. (25), the variation must be equal to zero for any δS1(x) and any δλ. This requires that each one of the expressions that appear in curly brackets vanish given that b(x) cannot be zero.

It follows that

Equation (26) determines that S1(x) must be uniform and thus independent of x. Therefore, it follows from the same equation that

Substituting the value of λ into Eq. (26) yields the solution for the axial strain S1(x) for the stationary (maximal) electrostatic energy:

In this study, we consider flexural vibrations in the transverse direction of the PVEH unimorph beam and specifically have the fundamental mode in mind. The same structure may of course vibrate in higher modes of transverse flexural vibrations as well as in other modes, such as lateral flexural vibrations and torsional (i.e., twisting) vibrations. In recent publications (Salman et al., 2024a, 2025), we investigated the optimal planform of a PVEH unimorph that maximizes the harvested energy. In those studies, the electrode covers the entire top side of the unimorph. In these cases, higher modes of transverse flexural vibrations are not optimal for harvesting energy since the axial strain S1 cannot be uniform (i.e., due to reversal of strain polarity at nodal points). Furthermore, if the planform of the unimorph is symmetric around the beam axis (as is often the case), then sideways deflections and torsional deformations are also ineffective for energy harvesting because they would result in a zero average value of S1 in the piezoelectric layer.

Another important issue to discuss is how accurate the assumption that bending is cylindrical is, which is the justification for ignoring the lateral strain S2. To this end, the analysis of Kaldor and Noyan (2002) is relevant, but in any case, in most applications in microelectromechanical systems (MEMS) the piezoelectric layer is deposited over a single crystalline silicon substrate with the beam axis in the stiffer [110] direction. In this [110] direction, the Poisson ratio is ν= 0.064, which means anticlastic bending is marginal (Salman et al., 2024b).

In our analysis, we only consider synchronous vibrations, in which the deflection is a product of a spatial mode and a single harmonic function of time. In many realistic scenarios, vibration may be better described as quasiperiodic, which includes many modes for which the different frequencies are not commensurate (i.e., the ratios between the frequencies is not a rational number). Obviously, in this case, the axial strain S1 cannot be uniform, and therefore for these cases, the analysis is not applicable.

This study presents a formal proof, showing that for a given amount of mechanical elastic energy stored in a PVEH, a uniform axial strain distribution within the thin piezoelectric layer maximizes the electrostatic energy. By designing a PVEH with specific distributions of inertia and of bending rigidity, we may achieve a uniform distribution of the axial strain S1 in the piezoelectric layer, resulting in a maximal electrostatic energy that can be harvested by the PVEH.

No data sets were used in this work.

ES contributed to the formal analysis and writing. DR contributed to the formal analysis and writing. DE contributed to the conception, formal analysis, supervision, funding acquisition and writing. All authors read and approved the final paper.

The contact author has declared that none of the authors has any competing interests.

Publisher’s note: Copernicus Publications remains neutral with regard to jurisdictional claims made in the text, published maps, institutional affiliations, or any other geographical representation in this paper. While Copernicus Publications makes every effort to include appropriate place names, the final responsibility lies with the authors.

This article is part of the special issue “Eurosensors 2024”. It is a result of the EUROSENSORS XXXVI, Debrecen, Hungary, 1–4 September 2024.

This research has been supported by the Israel Science Foundation (grant no. 1820/22).

This paper was edited by Péter Fürjes and reviewed by two anonymous referees.

Baker, J., Roundy, S., and Wright, P.: Alternative geometries for increasing power density in vibration energy scavenging for wireless sensor networks, in: 3rd International Energy Conversion Engineering Conference, San Francisco, California, 15–18 August 2005, 959–970, https://doi.org/10.2514/6.2005-5617, 2005.

Benasciutti, D., Moro, L., Zelenika, S., and Brusa, E.: Vibration energy scavenging via piezoelectric bimorphs of optimized shapes, Microsyst. Technol., 16, 657–668, https://doi.org/10.1007/s00542-009-1000-5, 2010.

Chen, Z. S., Yang, Y. M., and Deng, G. Q.: Analytical and experimental study on vibration energy harvesting behaviors of piezoelectric cantilevers with different geometries, in: 1st International Conference on Sustainable Power Generation and Supply, Nanjing, China, 6–7 April 2009, 1–6, https://doi.org/10.1109/SUPERGEN.2009.5348290, 2009.

Dietl, J. M. and Garcia, E.: Beam shape optimization for power harvesting, J. Intel. Mat. Syst. Str., 21, 633–646, https://doi.org/10.1177/1045389X10365094, 2010.

Du, S., Jia, Y., Chen, S.-T., Zhao, C., Sun, B., Arroyo, E., and Seshia, A. A.: A new electrode design method in piezoelectric vibration energy harvesters to maximize output power, Sensors Actuators A Phys., 263, 693–701, 2017.

Erturk, A. and Inman, D. J.: Issues in mathematical modeling of piezoelectric energy harvesters, Smart Mater. Struct., 17, 65016, https://doi.org/10.1088/0964-1726/17/6/065016, 2008.

Erturk, A. and Inman, D. J.: An experimentally validated bimorph cantilever model for piezoelectric energy harvesting from base excitations, Smart Mater. Struct., 18, 25009, https://doi.org/10.1088/0964-1726/18/2/025009, 2009.

Erturk, A. and Inman, D. J.: Piezoelectric energy harvesting, Chichester, Wiley, https://doi.org/10.1002/9781119991151, 2011.

Gallina, M. and Benasciutti, D.: Finite element analysis of optimized piezoelectric bimorphs for vibrational “energy harvesting,” in: International CAE Conference 2013, Pacengo del Garda, Verona, Italy 21–22 October 2013, 1–4, https://www.researchgate.net/profile/Denis-Benasciutti/publication/257929811_Finite_element_analysis _of_optimized_piezoelectric_bimorphs_for_vibrational_energy_ harvesting/links/00b4952640bdd844ef000000/Finite-element-analysis-of-optimized-piezoelectric-bimorphs-for-vibrational-energy-harvesting.pdf (last access: 1 July 2024), 2013.

Ikeda, T.: Fundamentals of piezoelectricity, Oxford University Press, ISBN 9780198563396, 1996.

Jia, Y. and Seshia, A. A.: Five topologies of cantilever-based MEMS piezoelectric vibration energy harvesters: a numerical and experimental comparison, Microsyst. Technol., 22, 2841–2852, https://doi.org/10.1007/s00542-015-2599-z, 2016.

Kaldor, S. K. and Noyan, I. C.: Differentiating between elastically bent rectangular beams and plates, Appl. Phys. Lett., 80, 2284–2286, https://doi.org/10.1063/1.1459762, 2002.

Karami, M. A., Bilgen, O., Inman, D. J., and Friswell, M. I.: Experimental and analytical parametric study of single-crystal unimorph beams for vibration energy harvesting, IEEE T. Ultrason. Ferr., 58, 1508–1520, 2011.

Krommer, M.: On the correction of the Bernoulli-Euler beam theory for smart piezoelectric beams, Smart Mater. Struct., 10, 668, https://doi.org/10.1088/0964-1726/10/4/310, 2001.

Lee, S., Youn, B. D., and Jung, B. C.: Robust segment-type energy harvester and its application to a wireless sensor, Smart Mater. Struct., 18, 095021, https://doi.org/10.1088/0964-1726/18/9/095021, 2009.

Lustig, S. and Elata, D.: Ambiguous definitions of the piezoelectric coupling factor, J. Intel. Mat. Syst. Str., 31, 1689–1696, https://doi.org/10.1177/1045389X20930104, 2020.

Meitzler, A. H., Tiersten, H. F., and Berlincourt, D.: IEEE standard on piezoelectricity: an american national standard, New York IEEE-ANSI, https://doi.org/10.1109/IEEESTD.1988.79638, 1988.

Miller, L. M., Halvorsen, E., Dong, T., and Wright, P. K.: Modeling and experimental verification of low-frequency MEMS energy harvesting from ambient vibrations, J. Micromech. Microeng., 21, 045029, https://doi.org/10.1088/0960-1317/21/4/045029, 2011.

Salman, E., Lustig, S., and Elata, D.: On the optimal planform of a cantilever unimorph piezoelectric vibrating energy harvester, Smart Mater. Struct., 33, 35029, https://doi.org/10.1088/1361-665X/ad28d0, 2024a.

Salman, E., Musnikov, L., Rosenstock, D., and Elata, D.: The Effect of Poisson Ratio and Beam Width on the Fundamental Frequency of a Cantilever Beam, IEEE Sensors Lett., 8, 1–4, https://doi.org/10.1109/LSENS.2024.3414668, 2024b.

Salman, E., Lustig, S., and Elata, D.: The optimal planform of a cantilever unimorph piezoelectric vibrating energy harvester (PVEH), with a device-layer edge block, in: Eurosensors 2024, 494–495, https://doi.org/10.5162/EUROSENSORSXXXVI/OT1.5, 2024c.

Salman, E., Lustig, S., and Elata, D.: The optimal planform of a cantilever unimorph piezoelectric vibrating energy harvester (PVEH) with a device-layer edge block, with a device-layer edge block, J. Sens. Sens. Syst., 14, 153–159, https://doi.org/10.5194/jsss-14-153-2025, 2025.

Tiersten, H. F.: Linear Piezoelectric Plate Vibrations: Elements of the Linear Theory of Piezoelectricity and the Vibrations Piezoelectric Plates, Plenum Press, New York, NY, ISBN 9781489962218, 1969.

Uchino, K.: Piezoelectric actuators and ultrasonic motors, Kluwer Academic Publishers, Boston, MA, ISBN 9780792398110, 1997.