the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

Reverse electrowetting-on-dielectric (REWOD) human energy harvester towards hybridisation with piezoelectricity for self-powered wearable biosensors

Sotiria D. Psoma

Ihor Sobianin

Antonios Tourlidakis

Wearable biosensors play a crucial role in modern healthcare, providing continuous monitoring of various physiological parameters. However, the reliance on batteries that require replacement introduces interruptions in the data acquisition process and patient discomfort, and for this reason, energy harvesting methods that convert human body energy into electricity have attracted considerable research interest. In this paper, the concept of an innovative hybrid energy harvester that combines piezoelectric and reverse electrowetting-on-dielectric (REWOD) techniques is introduced. The key working principle revolved around the electrical double layer present in the REWOD component and coupling it with a piezoelectric generator via an electret. By harnessing biomechanical vibrations with a piezoelectric material and the REWOD unit, the overall power output of the harvester was enhanced. The proposed design was evaluated through numerical simulations and a series of experimental tests. In the present work, experimental results on the influence of various design parameters on the amount of generated power through the REWOD process are presented, thus contributing to the advancement of self-powered, sustainable, wearable biosensors, enabling seamless and continuous data acquisition without relying on external batteries.

- Article

(5251 KB) - Full-text XML

- BibTeX

- EndNote

Modern healthcare relies extensively on implantable and wearable biosensors to continuously monitor the physiological data of patients. These devices can play a crucial role among others in disease prevention, treatment of injuries, and facilitating recovery (Gambhir Sanjiv et al., 2021). However, a significant drawback of biosensors lies in their reliance on batteries for power supply and batteries present in biosensors pose challenges such as miniaturisation, potential electrolyte leakage, and costly replacement surgeries for implantable devices (Ryu et al., 2021). For instance, wearable glucose biosensors require the battery to be periodically changed, which introduces a discontinuity in data acquisition and discomfort due to skin penetration.

These limitations can be addressed through the development of energy harvesting devices. The human body has multiple energy sources that can be effectively harnessed by various transducers (Sobianin et al., 2022). These sources include thermal energy, biochemical reactions, electrostatic charges, and biomechanical forces. However, relying solely on a single energy type may not yield optimal power output or guarantee that the energy is constantly available. Therefore, hybrid energy harvesters that combine multiple energy generators can enhance overall performance.

The human body is potent with chemical, thermal, and biomechanical energy types, all of which can be exploited by nanogenerators (NGs), materials, and devices that produce electricity upon being excited. From a biomechanical perspective, the human body has many points of concentrated pressure, bending, and angular movement. Piezoelectric NGs (PENG) produce voltage when subjected to mechanical stress and combine ease and cost of manufacturing with excellent electrical properties. This makes them an excellent candidate for hybridisation.

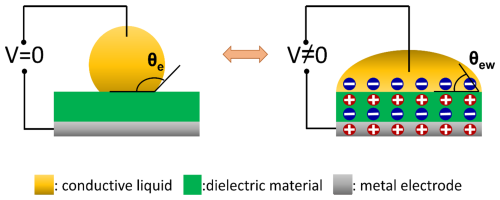

Recently, considerable attention has been drawn to the reverse electrowetting-on-dielectric (REWOD) phenomenon (Boroujeni et al., 2020; Wu et al., 2020; Adhikari et al., 2021). This is a prominent subclass of electrostatic generators (ESGs), which is based on the direct electrowetting-on-dielectric (EWOD) phenomenon. The surface tension of the solid–liquid interface can be changed by the application of electrical voltage, which will rearrange the charges and dipoles at the interface (Kim et al., 2020). This leads to a change in the apparent contact angle (CA) between the droplet and the electrode which increases the overlap area (Fig. 1). The Young–Lippman equation relates the energy of the droplet system and the external voltage (Mugele and Baret, 2005) and describes a given EWOD system working principle:

where θe is the equilibrium CA between two fluids at zero bias, σ12 is the surface tension at the interface between two fluids or the interfacial energy, is the areal capacitance, ε and ε0 are the dielectric and vacuum permittivity respectively, df is the dielectric layer thickness, and V is the applied potential difference. The capacitance of the system is given by C=CarealA, where A is the area of overlap of the droplet with the dielectric-coated electrode.

Figure 1Working principle of the EWOD phenomenon: when no voltage is applied, the droplet of conductive liquid forms a liquid–solid interface with the dielectric material. The CA at the interface can be manipulated by applying voltage between the droplet and the electrode.

To avoid electrolysis of the liquid, a dielectric material is used as an intermediate layer between the electrode and the liquid (Mugele and Baret, 2005). The solid–liquid interface is characterised by a Helmholtz electrical double layer (EDL), where charges of the opposite polarities build up, thus forming a capacitor. However, the capacitance of the EWOD system is largely defined by the dielectric layer (Wei et al., 2024). It is considered that the EDL is much smaller than the dielectric capacitance. A droplet could potentially be a physiological fluid (Srinivasan et al., 2004), and thus biomolecular absorption should be taken into account (Yoon and Garrell, 2003).

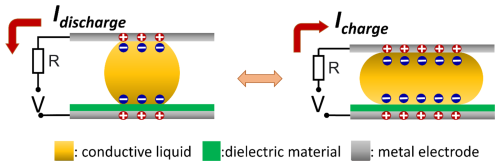

REWOD works in the opposite manner compared to EWOD, and when a droplet of a conductive liquid is pressed in-between electrodes (Fig. 2), the overlap area changes and this significantly changes the capacitance of the system, similarly to a varying capacitor (Meninger et al., 2001). The EDL, which is formed at both electrodes, contributes to the overall charge carried by the system. By changing the overlap area of the droplet, the charge Q (C) that is present on the electrode starts to change, which apparently is the definition of electrical current:

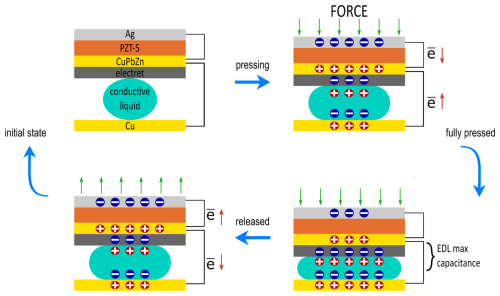

Figure 2Working principle of the REWOD phenomenon: the ions present in a liquid bind to a solid surface and are balanced by oppositely charged particles. When the droplet is squeezed, the surface area covered by the liquid increases, which also increases the number of ions that are in contact with the solid surface, thus inducing larger charge per unit of area. By repeating the cycle of wetting and de-wetting of the solid surface, it is possible to generate electrical current (Hsu et al., 2015).

There are systems that use EWOD for the purpose of microfluidics such as OpenDrop (Alistar and Gaudenz, 2017) and µDroplet (https://github.com/CGrassin/microdroplet_electrowetting, last access: 15 October 2025). In these systems, the direct EWOD effect is employed to navigate, disperse, and mix droplets of various origins. The important information that was obtained from these projects was how these systems tackle the issue of having a thin dielectric layer deposited on top of an electrode. In µDroplet this issue is solved via covering electrodes with stretched Parafilm, which has a thickness of 12 µm after stretching. Furthermore, a thin layer of silicon oil is deposited on top to enhance hydrophobic properties of the surface. In OpenDrop a stretched PTFE foil (Teflon) is used for the same purpose, while the hydrophobic properties were provided by spincoating a 200 µL FluoroPel solution.

For REWOD applications, usually a thin dielectric layer is utilised. For example, similar works in the field use vapour deposition techniques to deposit a dielectric layer of either Al2O3 (Adhikari et al., 2022a; Yang et al., 2017) or SiO2 (Adhikari et al., 2022b). One way of overcoming the use of complex deposition techniques is to refer to the solutions used by OpenDrop and µDroplet. However, the films that are produced in this way have a certain range of thickness values and cannot be accurately controlled. Furthermore, such films are prone to damage. In the practice of manufacturing PCB, a thin dielectric layer, a solder mask, is used to cover all regions of the PCB but the dedicated contact pads. This layer is 10–15 µm thick with a dielectric constant ε= 3.8 and could be used for the purpose of both EWOD droplet manipulation or REWOD energy harvesting.

There is an emerging trend of using a so-called bias-free REWOD, where no bias voltage is applied to the REWOD electrodes (Adhikari et al., 2022b, 2021). Kakaraparty et al. (2023), for instance, employed this concept to design a REWOD unit with flexible dissimilar electrodes generating 6.059 µW. Schumacher et al. (2024) developed an encapsulated flexible REWOD unit that is suitable for applications where pressure or bending is the main source of displacement with 5.77 nW output, which could be scaled up. The advantage of the bias-free method is that the REWOD harvester will not require any external input and thus it becomes self-sufficient. Thus, the REWOD setup that was used in this work did not have any external voltage applied to it.

In our previous work (Sobianin et al., 2023), we numerically studied the possibility of hybridisation of REWOD phenomenon and piezoelectric nanogenerator for the purpose of harvesting energy of the radial artery pulsations. Furthermore, another study of ours (Sobianin et al., 2024) focused on the development of a piezoelectric energy harvester suitable for integration with wrist-mounted devices. The work carried out in the current study focuses on the design of practical hybrid REWOD and piezoelectric energy harvester and empirical data acquisition. Therefore, the same low-frequency range of 60 to 150 bpm is used in this work during the series of experiments to assess the output of the synthesised energy harvester.

The objective of this study is to investigate the amount of biomechanical energy produced by the human cardiovascular system that can be harvested. More specifically, pulsations from the radial artery serve as a reliable source of vibrations that can be scavenged. The proposed hybrid energy harvester combines piezoelectric and electrostatic generators to extract energy from a time-varying radial artery pressure.

2.1 Description of the energy harvester

The hybrid energy harvester consists of two main parts: a piezoelectric disc and a REWOD component. The piezoelectric disc incorporating PZT-5H ceramics is commercially available (RS components). The ceramics is deposited onto a brass diaphragm (CuPbZn) and is coated with silver (Ag). The REWOD component consists of a shared brass electrode coated with an aluminised Teflon fluorinated ethylene propylene (FEP) electret and a counter electrode (Cu). The counter electrode is harnessed by a custom-designed printed circuit board (PCB). Finally, the conductive liquid used in the system is NaCl.

The working principle of the proposed hybrid energy harvester can be explained in the following way (Fig. 3). At the initial state, piezoelectric material and REWOD are at equilibrium and there is no electron flow. When the PENG is actuated by external pressure, the sustained deformation causes electron flow from one electrode to another, and one electrode obtains positive potential. The FEP electret, which is on top of the shared electrode, biases the REWOD component and therefore prevents ions and counter ions in the EDL from switching places (Erturun et al., 2021; Yang et al., 2012, 2014). The EDL which forms on top of the electret increases the overall capacitance of the system and maximises charge generation. At the same time, the REWOD counter electrode becomes more positive. When the pressure is released and the harvester moves back to its initial state, the process repeats itself with electrons moving in the opposite direction.

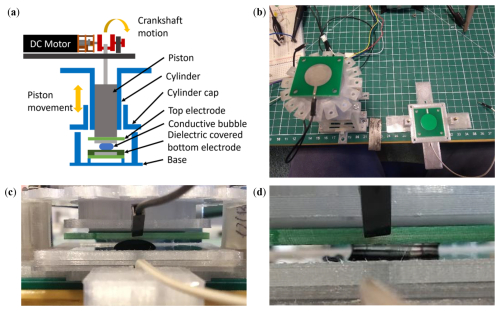

The REWOD experimental setup is derived from the piezoelectric material exciter from our previous work (Sobianin et al., 2023) where an oscillating piston driven by a DC motor through a crankshaft causes the movement of the upper electrode of a REWOD component. The cylinder was shortened significantly, and the cap was made hollow (Fig. 4a). The cylinder cap is screwed on top of the cylinder until their bottom edges line up (Fig. 4b). The base of the setup acts as a harness for the bottom electrode which has the solder mask applied to it. It is possible to add a frame with a dielectric film to this configuration if this is required. The rest of the setup rests on support pillars. All parts are tightly fixed together with two guiding screws. The top electrode was fixed to the piston with a help of double-sided sticky tape. The droplet of conductive liquid, 150 µL of 1 M NaCl, is deposited on top of the dielectric-coated electrode and subsequently the rest of the setup is placed on the top of it (Fig. 4c). When the droplet encounters the top electrode, a capillary bridge is formed, and the shape of the droplet changes (Fig. 4d).

Figure 4(a) Schematic of the REWOD setup. (b) Photograph of the REWOD setup. (c) A droplet deposited on top of the dielectric-coated electrode. (d) Formation of a capillary bridge.

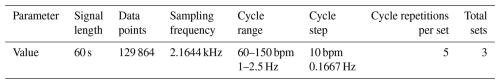

For the data acquisition, a Rohde & Schwarz RTB2004 oscilloscope with 1× probes was used. The main acquisition parameters can be found in Table 1. Due to the highly dynamic nature of a droplet-based experiment and its evaporation rate, the results presented are obtained from five cycle repetitions.

The sampling frequency of 2.1644 kHz, as presented in Table 1, is a derived value based on the set signal length and number of data points during our experimental measurements. It is provided for reference to characterise the data acquisition parameters. The critical aspect was ensuring high-quality and reliable data acquisition for accurately characterising the prototype's performance, which was achieved through the combination of signal length and data points.

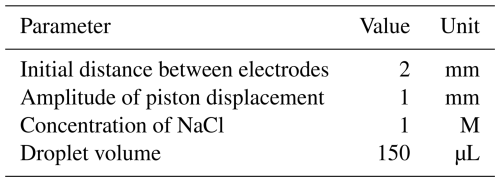

The so-called “baseline” case is the configuration of the setup that served as a comparison for other cases when any parameter was changed. All main entries are compiled in Table 2.

The effect of the following parameters on the performance of the REWOD experiment was investigated:

-

initial distance between the electrodes,

-

amplitude of the piston displacement,

-

concentration of NaCl, and

-

droplet volume.

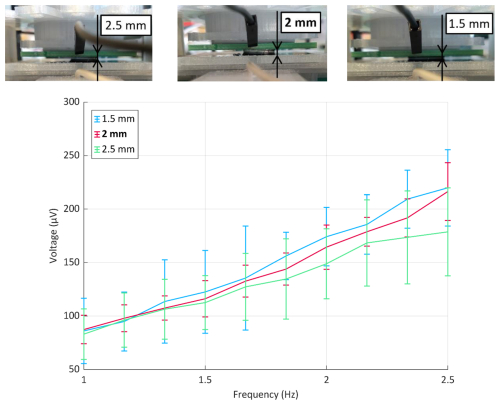

2.2 Effect of the initial distance between the electrodes

The change in height or initial distance between the electrodes was carried out by changing pillars. In this study, the effect of three initial distances between the electrodes or height values were analysed (Fig. 5). It should be noted that values lower than 1.5 mm resulted in the droplet being squeezed out from the two electrodes and values higher than 2.5 mm were too high for the droplet to come in contact with the top electrode. It was found that at low frequencies there were no significant differences between the height values. However, as the actuation frequency increased, the difference between the height values became more evident (Fig. 5). Yet, voltage output for 1.5 and 2 mm seemed to converge to a value of 215 µV. The overall trend was that the lower the distance between the electrodes, the higher the output, which can be explained through the greater change in droplet surface area coverage as the distance decreases.

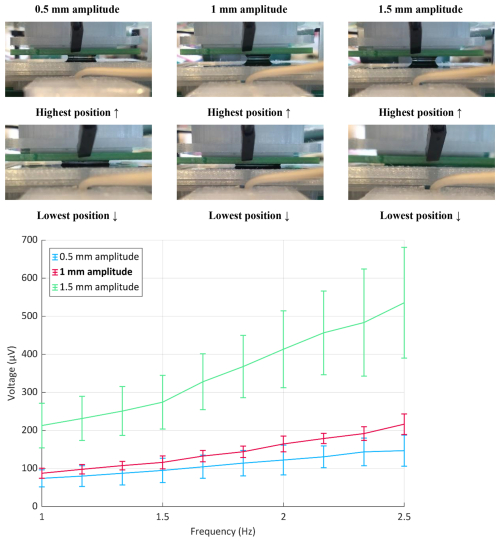

2.3 Study of the piston displacement amplitude

New crankshafts with different centrelines were manufactured in order to provide the test with three different displacement amplitude values. The studied values were 1.5, 1, and 0.5 mm displacement amplitudes (Fig. 6). Similarly to the height study, the value of 2 mm was too high to be used as it squeezed the droplet out of the actuation zone at the lowest position and amplitude values below 0.5 mm were challenging to manufacture with the FFF method. As for the results, higher values of amplitude modulated the overlapping area of the electrode and the conductive droplet to a much greater degree, thus having larger capacitance variation, which in turn induced higher voltage spikes (Fig. 6). It was observed that higher amplitudes had a steeper increase after the 1.5 Hz mark. This might potentially be related to how DCA works at high frequencies. Furthermore, the 0.5 mm amplitude case did not seem to have that high drop in performance as compared to the 1.5 mm case.

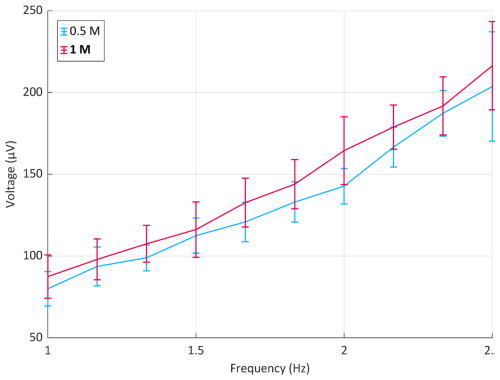

2.4 Effect of the NaCl concentration

The concentration of ions in the liquid plays a key role in how well it can conduct the current. Consequently, the baseline concentration of 1 M of NaCl was compared to 0.5 M, and the subsequent result showed that the 1 M solution is better suited to for the application of energy harvesting however the output produced by the 0.5 M solution was quite close to that of the baseline (Fig. 7). In practice, it means that it is possible to reduce the quantity of NaCl required to one-half, while the output power experiences a drop of only 13 µV, or 6 % as compared to the baseline value, which is important when factoring in the manufacturing cost of the REWOD harvester.

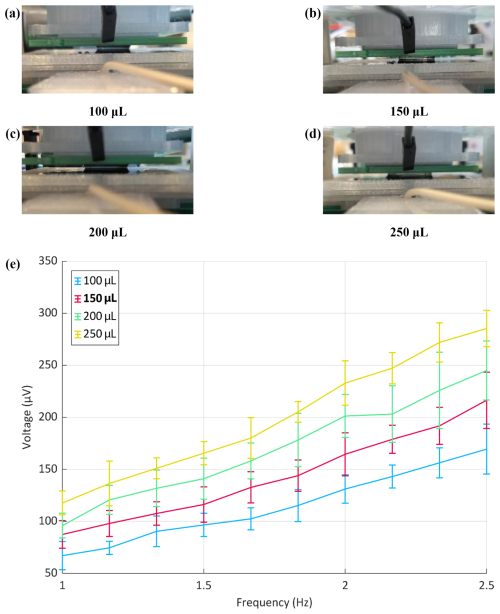

2.5 Parametric study of the droplet volume

The droplet volume determines how many ions are in contact at the same time and this dictates the charge which is present on the dielectric-coated electrode. The larger the droplet, the higher the output can become. For the present study, a range of droplets from 100 to 250 µL were investigated and the results are presented in Fig. 8. Furthermore, by decreasing the droplet volume from 150 to 100 µL there was a small decrease in voltage from 216 to 169 µV, whereas an increase in the droplet volume to 250 µL led to a maximum electrical power output of 285 µV (Fig. 8). Overall, it could be concluded that the droplet volume and the voltage output for the studied setup parameters had almost a linear relationship.

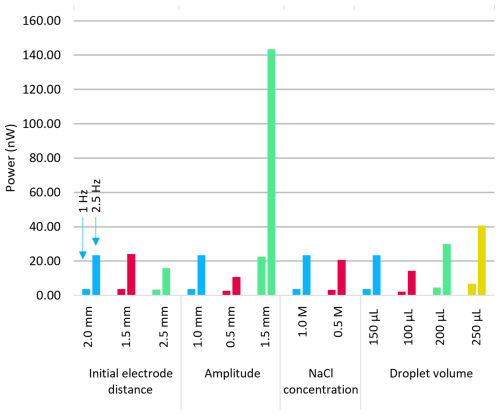

2.6 Power output comparison

The average power that is generated by the experimental setup can be calculated as the maximum value of the square of the RMS voltage. This calculation assumes that the given signal consists of a pure sinusoidal wave and that the resistance R=1 Ω.

As a result, the average generated power of 143.36 nW was obtained at 2.5 Hz with 2.5 mm displacement amplitude among all other configurations (Fig. 9). It was observed that this parameter played a significant role in the power output. Furthermore, even at 1 Hz, 2.5 mm amplitude yielded 22.65 nW of power, which was similar to what other parameters generated only at 2.5 Hz. This demonstrates the importance of having large variations in capacitance, which can be achieved by increasing the active surface area by using, for example, porous electrodes (Ali et al., 2023).

Similarly, the next largest contributor to the power output was the volume of the droplet. The initial distance between electrodes seemed to reach a point of saturation where a further decrease in the distance beyond 2 mm was not as effective. Lastly, the influence of frequency on the output results remained invariant of the studied parameter. This necessitates investigation into self-oscillating systems and other means of increasing the actuation frequency.

This work presents a novel hybrid energy harvester designed to convert biomechanical vibrations into electrical energy. While the prototype demonstrates a proof-of-concept with an average power output of 143.36 nW, it is crucial to address its current limitations and future potential, particularly in comparison to established power sources and in the context of wearable applications.

Firstly, regarding the energy density in comparison to conventional batteries, especially coin cells, it is important to clarify the distinction between an energy harvester and an energy storage device. Typical CR2032 coin cells, which are common lithium–manganese dioxide primary (non-rechargeable) batteries, provide a nominal voltage of 3.0 V and a typical capacity of 235 mA h, with a typical weight of 3.0 g, according to the ENERGIZER CR2023 data sheet. This translates to an approximate gravimetric energy density of 198 W h kg−1 for the CR2032. While these primary cells are suited for low-drain, long-life applications, their electrochemical principles differ from rechargeable lithium-ion (Li-ion) batteries.

In broader context, rechargeable lithium-ion batteries, which are the leading technology for high-energy-density applications like portable electronics and electric vehicles, typically exhibit gravimetric energy densities ranging from 200 to 300 W h kg−1 for standard chemistries (Niu et al., 2024). Advanced Li-ion battery technologies, including those utilising lithium-rich manganese-based cathodes or silicon/lithium metal anodes, are pushing these boundaries, with some commercially available options reaching around 300–360 W h kg−1 for mass production (Li et al., 2024). Furthermore, laboratory demonstrations and cutting-edge research have achieved gravimetric energy densities exceeding 700 W h kg−1 for full cells in rechargeable lithium batteries (Li et al., 2024). The development of high-energy-density lithium-ion batteries continues to be an active area of research, focusing on optimising materials and mitigating degradation mechanisms (Manthiram, 2017; Vetter et al., 2005). The advantage of our proposed harvester lies in its continuous energy generation, eliminating the need for battery replacement, which is a significant benefit for long-term wearable applications.

Secondly, concerning the mass and wearability of the harvester, the current experimental setup represents an early-stage prototype. Its dimensions and weight are not yet optimised for miniaturisation and seamless integration into truly wearable devices. This initial study focused solely on validating the innovative hybrid concept combining piezoelectric and REWOD techniques. Future iterations will prioritise significant miniaturisation and mass reduction to ensure the development of a lightweight, flexible, and comfortable device that can be worn without hindering user comfort or mobility. This will solidify the argument for battery independence in practical contexts.

Furthermore, while the generated power of 143.36 nW is modest, this work is fundamentally a proof-of-concept validating a novel hybrid energy harvesting mechanism. The primary objective was to demonstrate the synergistic effects of combining piezoelectric and REWOD techniques for energy conversion from biomechanical sources. This foundational work lays the groundwork for future developments where optimised materials and scaled-up designs are anticipated to significantly enhance power output. The principle that any usable energy from such a mechanism holds potential for future scalability is key. Although the current output is insufficient for most complex wearable biosensors, which typically require microwatts to milliwatts of power (Roy et al., 2022), a scaled-up version could eventually power ultra-low-power bioelectronic components. Examples include heart rate monitors, glucose sensors and general low-power biomedical signal monitoring systems for wearable and implantable sensors. The long-term vision is to evolve this technology to support continuous monitoring applications with reduced reliance on traditional batteries.

Finally, we envision this energy harvester being integrated into various wearable devices, primarily in wrist-mounted applications. Building on our prior work (Sobianin et al., 2024) on piezoelectric energy harvesters for wrist-mounted devices, this hybrid design is specifically tailored to leverage biomechanical vibrations, particularly those originating from radial artery pulsations in the wrist. This positioning can be used for powering low-power, continuous monitoring systems such as wearable glucose biosensors and other health monitoring wearables that benefit from continuous on-body power generation.

A series of experiments exploring the REWOD phenomenon for energy harvesting were conducted. The contactless exciter setup was used as a foundation for the REWOD experimental setup. This modification was built around the bias-free REWOD concept and using widely available PCBs to create dielectric coating and electrodes. The baseline setup featured a 1 M NaCl 150 µL droplet deposited on the solder-mask-coated electrode. The initial distance between the electrodes was 2 mm and the baseline actuation amplitude was 1 mm, which yielded the maximum of 216 µV at 2.5 Hz (150 bpm). A study investigating the change in the initial distance between the electrodes from 1.5 to 2.5 mm showed that the output voltage increases as the distance decreases; however the difference between 2 and 2.5 mm was not significant. The amplitude influence study showed that an increase in the amplitude to 1.5 mm actuates the droplet to a much greater extent than the baseline value. This suggests the importance of increasing the active surface area. The study of concentration of NaCl showed that the solution with only one-half of the salt concentration had relatively good performance, only dropping by 6 % from the baseline value. Finally, the effect of the droplet volume was studied: the overall trend appeared to be almost linear, where droplets with larger volume induced higher voltage output.

The design concept of the PENG-REWOD harvester could be improved further by making the chamber more flexible and allowing more movement for the droplet, and the power output could be increased through bias voltage. It might be beneficial to couple the REWOD unit with a thermoelectric energy harvester. In this case, the thermoelectric harvester, which should be as close as possible to the skin, can be directly connected to REWOD electrodes since its output does not need rectification.

All of the data in this work were generated by the authors and are available upon request.

Conceptualisation, SDP; methodology, AT, SDP and IS; formal analysis, IS; investigation, IS, SDP and AT; resources, SDP; data curation, IS and SDP; writing original draft preparation, IS and AT; writing, review and editing, SDP and AT; visualisation, IS, SDP and AT; supervision SDP and AT; project administration, SDP; funding acquisition, SDP All authors have read and agreed to the published version of the article.

The contact author has declared that none of the authors has any competing interests.

Publisher’s note: Copernicus Publications remains neutral with regard to jurisdictional claims made in the text, published maps, institutional affiliations, or any other geographical representation in this paper. While Copernicus Publications makes every effort to include appropriate place names, the final responsibility lies with the authors. Views expressed in the text are those of the authors and do not necessarily reflect the views of the publisher.

This article is part of the special issue “Eurosensors 2024”. It is a result of the EUROSENSORS XXXVI, Debrecen, Hungary, 1–4 September 2024.

The present research was supported by the Faculty of Science, Technology, Engineering and Mathematics at the Open University and by Higher Education Innovation Funding (England) through a Knowledge Transfer Voucher.

This paper was edited by Michael Kraft and reviewed by three anonymous referees.

Adhikari, P. R., Tasneem, N. T., Reid, R. C., and Mahbub, I.: Electrode and electrolyte configurations for low frequency motion energy harvesting based on reverse electrowetting, Scientific Reports, 11, 5030, https://doi.org/10.1038/s41598-021-84414-3, 2021.

Adhikari, P. R., Patwary, A. B., Kakaraparty, K., Gunti, A., Reid, R. C., and Mahbub, I.: Advancing Reverse Electrowetting-on-Dielectric from Planar to Rough Surface Electrodes for High Power Density Energy Harvesting, Energy Technology, 10, 2100867, https://doi.org/10.1002/ente.202100867, 2022a.

Adhikari, P. R., Reid, R. C., and Mahbub, I.: High power density and bias-free reverse electrowetting energy harvesting using surface area enhanced porous electrodes, Journal of Power Sources, 517, 230726, https://doi.org/10.1016/j.jpowsour.2021.230726, 2022b.

Ali, A., Shaukat, H., Bibi, S., Altabey, W. A., Noori, M., and Kouritem, S. A.: Recent progress in energy harvesting systems for wearable technology, Energy Strategy Reviews, 49, 101124, https://doi.org/10.1016/j.esr.2023.101124, 2023.

Alistar, M. and Gaudenz, U.: OpenDrop: An Integrated Do-It-Yourself Platform for Personal Use of Biochips, Bioengineering, 4, 45, https://doi.org/10.3390/bioengineering4020045, 2017.

Boroujeni, F. G., Raissi, B., Jafarabadi-Ashtiani, S., Riahifar, R., and Sahba-Yaghmaee, M.: Droplet-based energy harvester considering electrowetting phenomena, Engineering Research Express, 2, 045028, https://doi.org/10.1088/2631-8695/abce98, 2020.

Erturun, U., Eisape, A. A., Kang, S. H., and West, J. E.: Energy harvester using piezoelectric nanogenerator and electrostatic generator, Applied Physics Letters, 118, 063902, https://doi.org/10.1063/5.0030302, 2021.

Gambhir Sanjiv, S., Ge, T. J., Vermesh, O., Spitler, R., and Gold Garry, E.: Continuous health monitoring: An opportunity for precision health, Science Translational Medicine, 13, eabe5383, https://doi.org/10.1126/scitranslmed.abe5383, 2021.

Hsu, T.-H., Manakasettharn, S., Taylor, J. A., and Krupenkin, T.: Bubbler: A Novel Ultra-High Power Density Energy Harvesting Method Based on Reverse Electrowetting, Scientific Reports, 5, 16537, https://doi.org/10.1038/srep16537, 2015.

Kakaraparty, K., Pineda, E. A., Reid, R. C., and Mahbub, I.: Advancement of Reverse Electrowetting-on-Dielectric With Flexible Electrodes for Bias-Free Energy-Harvesting Applications, IEEE Sensors Journal, 23, 10334–10341, https://doi.org/10.1109/JSEN.2023.3264103, 2023.

Kim, J.-H., Lee, J.-H., Mirzaei, A., Kim, H. W., Tan, B. T., Wu, P., and Kim, S. S.: Electrowetting-on-dielectric characteristics of ZnO nanorods, Scientific Reports, 10, 14194, https://doi.org/10.1038/s41598-020-71017-7, 2020.

Li, Q., Yu, X., Li, H., and Chen, L.: The road towards high-energy-density batteries, The Innovation Energy, 1, 100005, https://doi.org/10.59717/j.xinn-energy.2024.100005, 2024.

Manthiram, A.: An Outlook on Lithium Ion Battery Technology, ACS Central Science, 3, 1063–1069, 2017.

Meninger, S., Mur-Miranda, J., Amirtharajah, R., Chandrakasan, A., and Lang, J.: Vibration-to-electric energy conversion, IEEE Trans. VLSI Syst., 9, 64–76, https://doi.org/10.1109/92.920820, 2001.

Mugele, F. and Baret, J.-C.: Electrowetting: from basics to applications, Journal of Physics: Condensed Matter, 17, R705–R774, https://doi.org/10.1088/0953-8984/17/28/R01, 2005.

Niu, H., Zhang, N., Lu, Y., Zhang, Z., Li, M., Liu, J., Zhang, N., Song, W., Zhao, Y., and Miao, Z.: Strategies toward the development of high-energy-density lithium batteries, Journal of Energy Storage, 88, 111666, https://doi.org/10.1016/j.est.2024.111666, 2024.

Roy, S., Azad, A. N. M. W., Baidya, S., Alam, M. K., and Khan, F.: Powering Solutions for Biomedical Sensors and Implants Inside the Human Body: A Comprehensive Review on Energy Harvesting Units, Energy Storage, and Wireless Power Transfer Techniques, IEEE Transactions on Power Electronics, 37, 12237–12263, https://doi.org/10.1016/j.jpowsour.2005.01.006, 2022.

Ryu, H., Park, H.-m., Kim, M.-K., Kim, B., Myoung, H. S., Kim, T. Y., Yoon, H.-J., Kwak, S. S., Kim, J., Hwang, T. H., Choi, E.-K., and Kim, S.-W.: Self-rechargeable cardiac pacemaker system with triboelectric nanogenerators, Nature Communications, 12, 4374, https://doi.org/10.1038/s41467-021-24417-w, 2021.

Schumacher, B. S., Sah, P. K., Kakaraparty, K., Mahbub, I., and Reid, R. C.: Reverse Electrowetting-on-Dielectric Energy Harvesting Using Inexpensive, Flexible Substrates, IEEE Sensors Journal, 24, 31875–31882, https://doi.org/10.1109/JSEN.2024.3450430, 2024.

Sobianin, I., Psoma, S. D., and Tourlidakis, A.: Recent Advances in Energy Harvesting from the Human Body for Biomedical Applications, Energies, 15, 7959, https://doi.org/10.3390/en15217959, 2022.

Sobianin, I., Psoma, S. D., and Tourlidakis, A.: A hybrid piezoelectric and electrostatic energy harvester for scavenging arterial pulsations, Materials Today: Proceedings, 93, 16–23, https://doi.org/10.1016/j.matpr.2023.05.213, 2023.

Sobianin, I., Psoma, S. D., and Tourlidakis, A.: A 3D-Printed Piezoelectric Microdevice for Human Energy Harvesting for Wearable Biosensors, Micromachines, 15, 118, https://doi.org/10.3390/mi15010118, 2024.

Srinivasan, V., Pamula, V. K., and Fair, R. B.: An integrated digital microfluidic lab-on-a-chip for clinical diagnostics on human physiological fluids, Lab. Chip, 4, 310–315, https://doi.org/10.1039/B403341H, 2004.

Vetter, J., Novák, P., Wagner, M. R., Veit, C., Möller, K. C., Besenhard, J. O., Winter, M., Wohlfahrt-Mehrens, M., Vogler, C., and Hammouche, A.: Ageing mechanisms in lithium-ion batteries, Journal of Power Sources, 147, 269–281, https://doi.org/10.1016/j.jpowsour.2005.01.006, 2005.

Wei, Z., Elliott, J. D., Papaderakis, A. A., Dryfe, R. A. W., and Carbone, P.: Relation between Double Layer Structure, Capacitance, and Surface Tension in Electrowetting of Graphene and Aqueous Electrolytes, Journal of the American Chemical Society, 146, 760–772, https://doi.org/10.1021/jacs.3c10814, 2024.

Wu, H., Mendel, N., van der Ham, S., Shui, L., Zhou, G., and Mugele, F.: Charge Trapping-Based Electricity Generator (CTEG): An Ultrarobust and High Efficiency Nanogenerator for Energy Harvesting from Water Droplets, Advanced Materials, 32, 2001699, https://doi.org/10.1002/adma.202001699, 2020.

Yang, H., Hong, S., Koo, B., Lee, D., and Kim, Y.-B.: High-performance reverse electrowetting energy harvesting using atomic-layer-deposited dielectric film, Nano Energy, 31, 450–455, https://doi.org/10.1016/j.nanoen.2016.11.006, 2017.

Yang, Z., Halvorsen, E., and Dong, T.: Power generation from conductive droplet sliding on electret film, Applied Physics Letters, 100, https://doi.org/10.1063/1.4720517, 2012.

Yang, Z., Halvorsen, E., and Dong, T.: Electrostatic Energy Harvester Employing Conductive Droplet and Thin-Film Electret, Journal of Microelectromechanical Systems, 23, 315–323, https://doi.org/10.1109/JMEMS.2013.2273933, 2014.

Yoon, J.-Y. and Garrell, R. L.: Preventing Biomolecular Adsorption in Electrowetting-Based Biofluidic Chips, Analytical Chemistry, 75, 5097–5102, https://doi.org/10.1021/ac0342673, 2003.